Our shockproof packaging solutions have been market leaders for a long time due to their high quality and minimal environmental impact. We use sustainable materials to manufacture the most efficient, durable, and climate-smart packaging possible, tailored to meet the specific needs of our customers. Our sustainable materials, combined with unique design, create packaging solutions that can protect fragile items well over an extended period.

We specialize in designing and manufacturing shock protection that effectively shields products from impacts and jolts. In some situations, it may be sufficient to package the product in a box if it either has built-in shock protection or is deemed not to require additional protection against impacts and jolts.

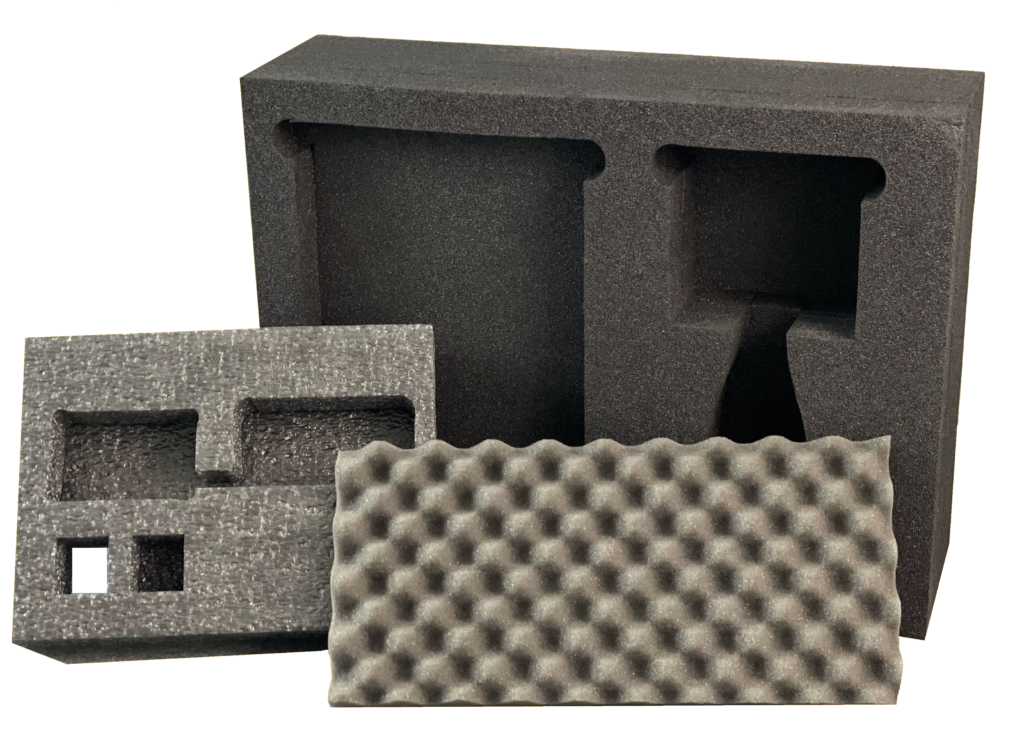

For more fragile items that require extra protection during transport, we create custom interiors optimized to ensure maximum protection, efficient material use, and easy handling during packing and unpacking. We are dedicated to delivering high-quality solutions that meet all needs for the best possible protection and handling.

For shipments between factories, ease of packing, ease of unpacking, and cost-efficiency are typically the main focus. For these purposes, we often use EPEL, a single-layered cellular plastic available in white and black, as well as various densities to customize the interior based on the weight of the products.

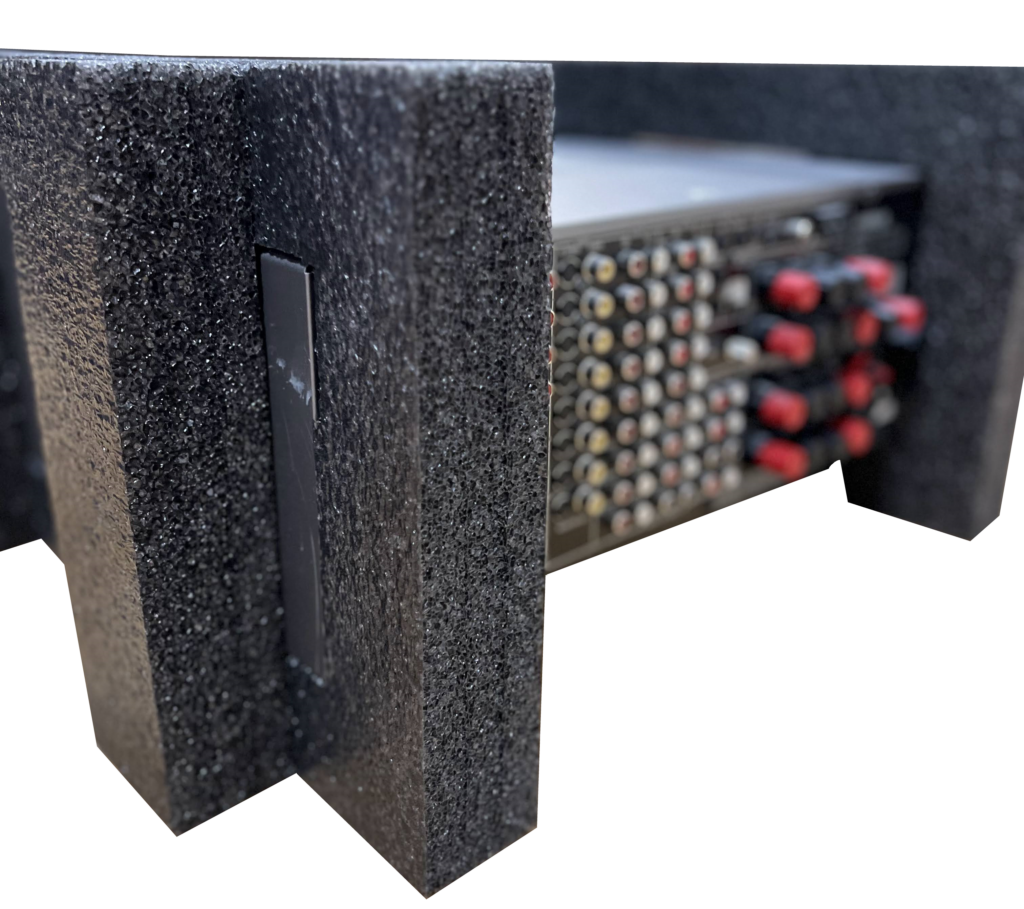

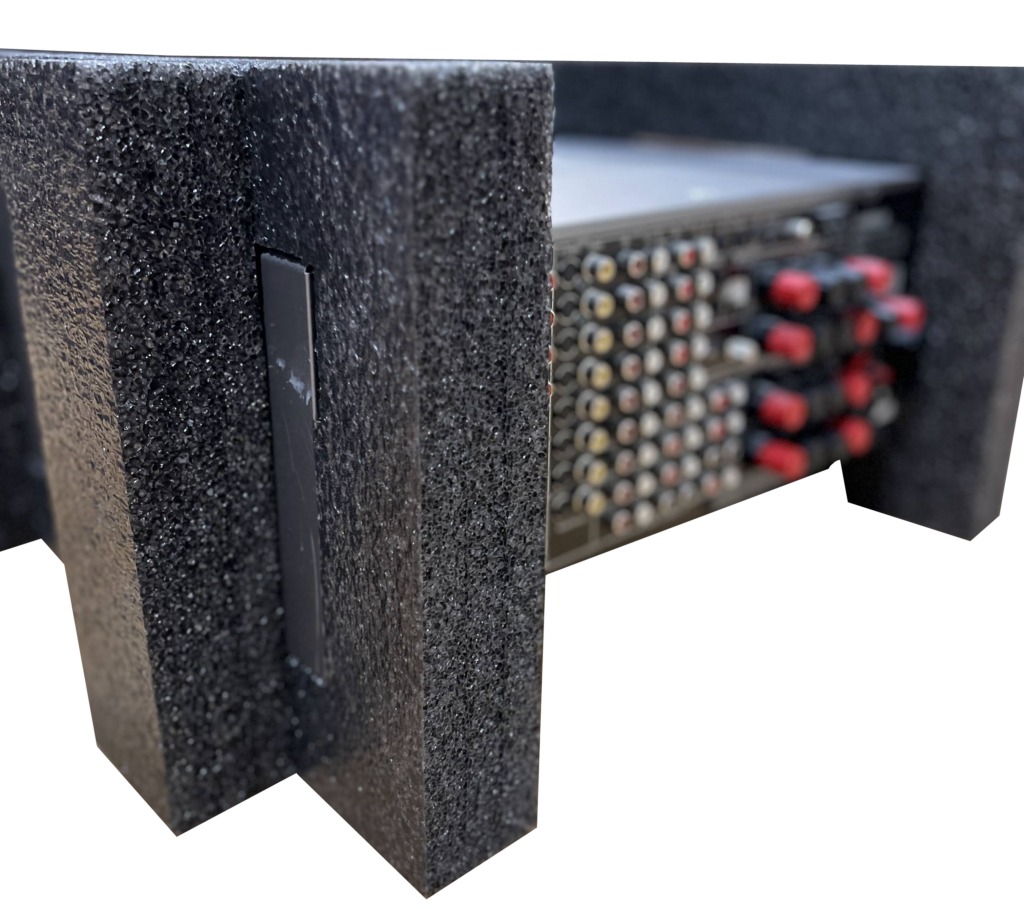

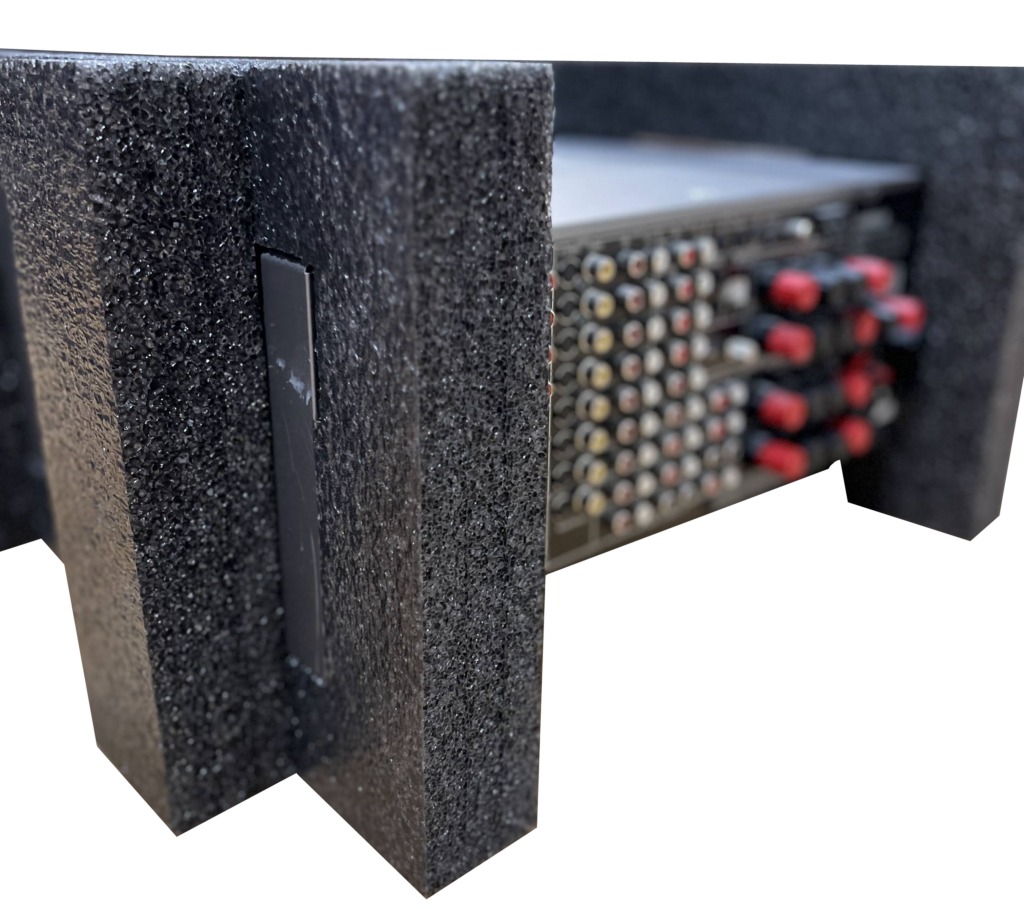

An alternative is corner supports, which are used to create space between the product and the walls of the box. For heavy products, a bottom-and-lid solution is recommended, where the product is placed in the box with the bottom inserted first and then the lid placed on top. This design allows for the simplest possible packing, minimizes material use, and facilitates both packing and recycling.

With these solutions, we offer cost-effective and environmentally friendly options for the safe and efficient transportation of products between factories.

In consumer packaging, appearance is a crucial factor. The packaging must be aesthetically pleasing from the outside and requires different box models to create the desired impression. Additionally, the product must be presented in an attractive and appealing manner using elegant interior design.

We offer several material options that provide a premium feel during product unpacking. One option is to use EPEX, a cross-linked cellular plastic that gives a more luxurious sensation. Alternatively, a custom die-cut insert made of corrugated cardboard can be used to convey a sense of naturalness and sustainability.

With these options, we can create packaging that is not only visually appealing but also provides consumers with a first-class experience when unpacking their new products.

Gavelstöd till multimediaspelare

-EPEL Renew

Låda med inrede

-EPEL Renew

Gavelstöd till multimediaspelare

-EPEL Renew

Låda med inrede

-EPEL Renew

Copyright © 2026 Team ET